Factory Direct Wholesale Paper Cup Fan

Description

| Product Name | Paper cup fan |

| Paper Weight | 150 ~ 350gsm |

| PE Coated Weight | 10 ~ 30gsm |

| Width | Custom manufacturing |

| Coating Side | Single and double side |

| Printing | 6 Colours flexo printing |

| Application | Paper cup for coffee, milk, ice cream, etc. Food container for lunch, soup, salad, etc. |

| Pulp Material | 100% wood pulp |

| Sample | Customized |

| Base Paper | Yibin, App, Enso, Ningpo, etc. |

| Size | 2~ 22OZ |

| Feature | Waterproof, oil-proof, resist high-temperature,

clear printing |

| Custom Order | Accept |

| MOQ | 5 tons |

| Lead Time | 20-30 days |

| FOB Port | QINZHOU,GUANGZHOU,SHENZHEN |

PAPER CUP FAN

*CHOOSE US IS TO CHOOSE A PROFESSIONAL RAW MATERIAL MANUFACTURER OF PAPER CUP

PRODUCTION DESCRIPTION

PAPER CUP FAN

Base Paper: 150 ~ 350gsm

PE Weight:10 ~30gsm

Material: Food grad

Certification: ISO,SGS,etc

Colour: 6 Colours and customized

Professional to provide raw materials for paper cups with one-stop products of paper cup fan, PE coated paper roll, PE coated paper sheet,PE coated paper bottom roll.

SHOW DETAILS

01. Food Grade Materials

1. Materials: Food grade PE materials

2.Certified: SGS, ISO, etc

02. Product Feature

1. Waterproof, oil-proof, resist high-temperature,

clear printing

03. Products Display

1. Easy to forming.

2. High quality of printing effect.

2. Appearance: smooth surface, without breakage, tidy.

3. Support matt lamination and bright lamination.

APPLICATIONS

PE coated paper cup fan can be widely used to make a variety of products, such as

1. Paper cup.

2. Paper bowls.

3. Food boxes, etc.

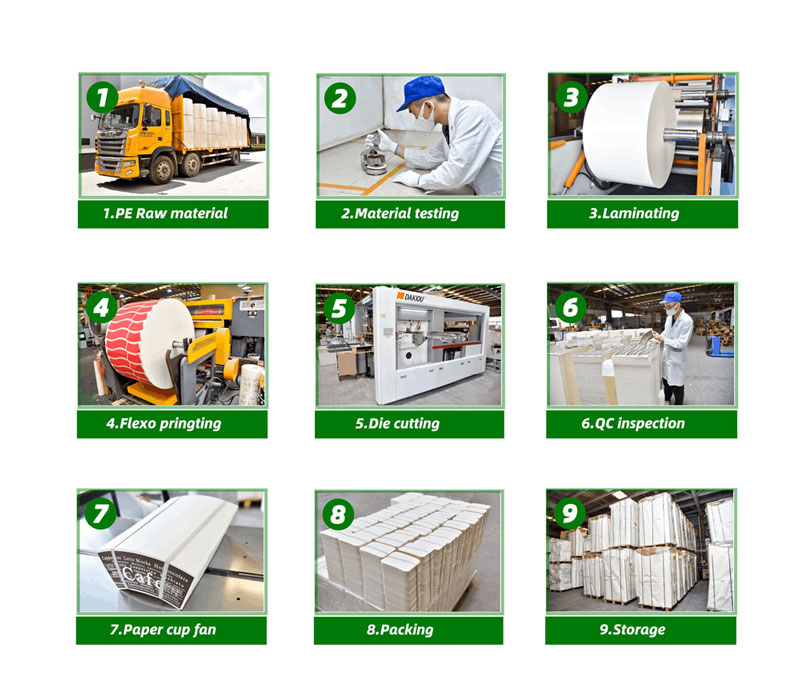

PRODUCTION FLOW

QUALITY CONTROL

Quality control is one of our very important procedure during the production. PE coating quality control as below.

1. Bace paper testing

2. Coating machine inspection

3. PE coating fastness verification

4. Roll tidy verification

5. Roll weight verification

6. Packing verification

PACKING SOLUTION